Turning Waste into Clean Energy

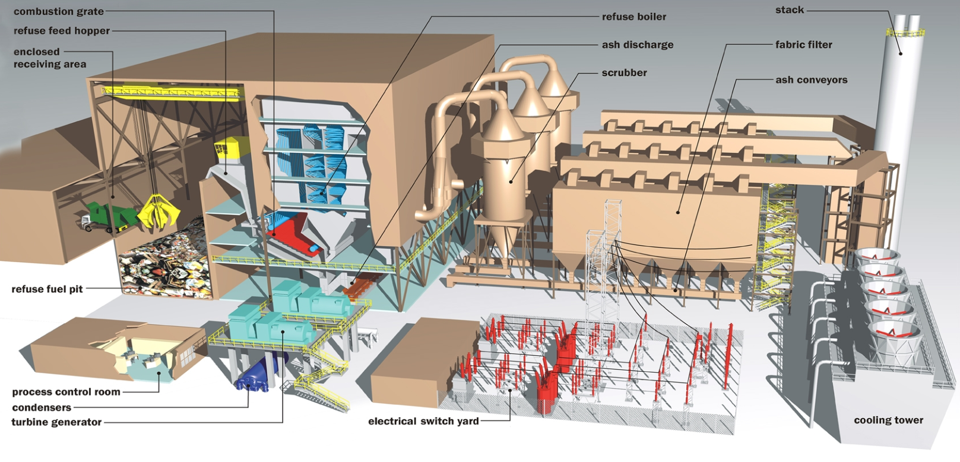

Waste-to-energy (WTE) power plants are innovative and sustainable solutions for addressing the increasing problem of urban waste accumulation, while simultaneously generating electricity. These facilities convert municipal waste into useful energy through various methods, significantly reducing environmental pollution and conserving natural resources.

The two main techniques employed in these technologies are pyrolysis and gasification.

Pyrolysis is a process in which waste materials are heated at high temperatures (typically between 400 to 700°C) in the absence of oxygen. During this process, the organic components in the waste break down to produce various products, including liquid fuels (like tar and oil), synthetic gases (syngas), and char (carbon-rich residue). This process substantially reduces the volume of waste and produces energy that can be used for electricity generation or heating purposes.

Gasification involves heating waste at high temperatures in a controlled environment with limited oxygen or in an oxygen-free setting. This converts the waste into syngas—mainly composed of hydrogen, carbon monoxide, and other combustible gases—which can then be cleaned and used to generate electricity or produce synthetic fuels.

One of the most significant advantages of these technologies is the remarkable reduction in waste volume, which alleviates the pressure on landfill sites. This not only makes waste management more efficient but also prevents the release of methane—a potent greenhouse gas—that is typically generated from organic waste decomposition in landfills.

Additionally, modern WTE plants are equipped with advanced pollution control systems such as filters, scrubbers, and catalytic converters, which substantially cut emissions of harmful pollutants into the air, soil, and water compared to traditional waste disposal and incineration methods.

These plants also play a crucial role in decreasing urban pollution caused by the accumulation of municipal waste. Converting waste into energy reduces the need for landfill space, prevents open burning, and minimizes nuisances like foul odors and visual blight. Consequently, they improve air quality, protect public health, and contribute to cleaner, more sustainable urban environments.

Furthermore, waste-to-energy facilities contribute to combating climate change by reducing greenhouse gas emissions, lowering reliance on fossil fuels, and promoting the use of renewable and cleaner energy sources. They provide a path toward a circular economy where waste is viewed as a resource rather than a problem.

In summary, employing pyrolysis and gasification techniques in waste-to-energy power plants offers a sustainable approach for waste management, environmental protection, and energy production. These technologies help reduce pollution, mitigate the effects of urban waste buildup, and support global efforts toward a greener, healthier planet.

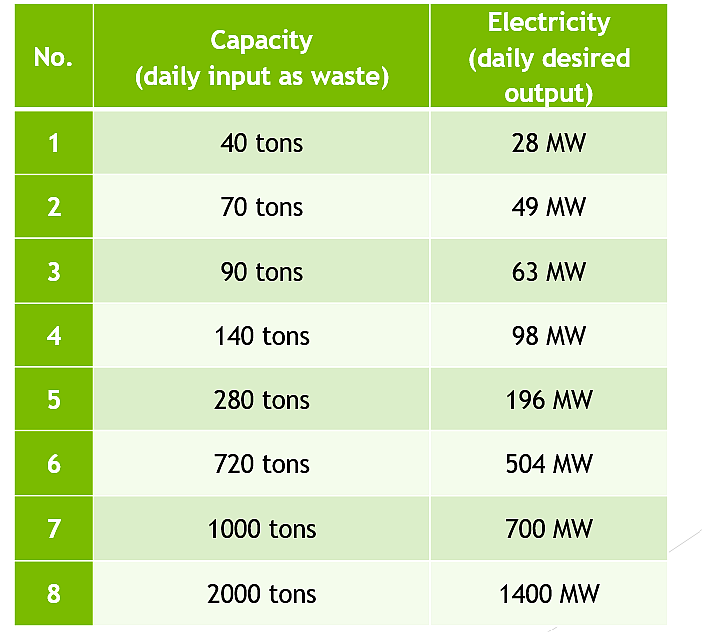

Average Electricity Production per Ton of Municipal Waste in Pyrolysis and Gasification Methods

Based on global studies and experiences, each ton of municipal waste processed through pyrolysis or gasification typically produces between 350 and 700 kilowatt-hours of electricity.

This figure varies depending on the type of waste, the percentage of organic materials, the technology used, and the efficiency of the equipment.

Average Estimate:

In most cases, it can be generally said that each ton of waste generates about 200 kilowatt-hours of electricity. This estimate has been confirmed by various projects in both developed and developing countries.

Suggested Sources:

- The United Nations and World Bank reports on waste management and renewable energy estimate the average electricity output in similar processes to be around 350-700 kWh per ton of waste.

- A study published in Renewable and Sustainable Energy Reviews (2018-2020) shows that successful projects in Asia and Europe can even reach up to 750 kWh.

- Modern technologies and advanced equipment can enhance efficiency, resulting in higher electricity generation.

Important Note:

The exact amount of electricity produced depends on the proportion of organic (carbon-rich) materials present in the waste and the specific technology employed. For example, wet waste or waste containing a higher percentage of inorganics tend to produce less electricity, while organic-rich and decomposable waste yields higher energy output.

Pyrolysis Full Process Flow Chart

Gasification diagram

Electricity Generation Capacity: