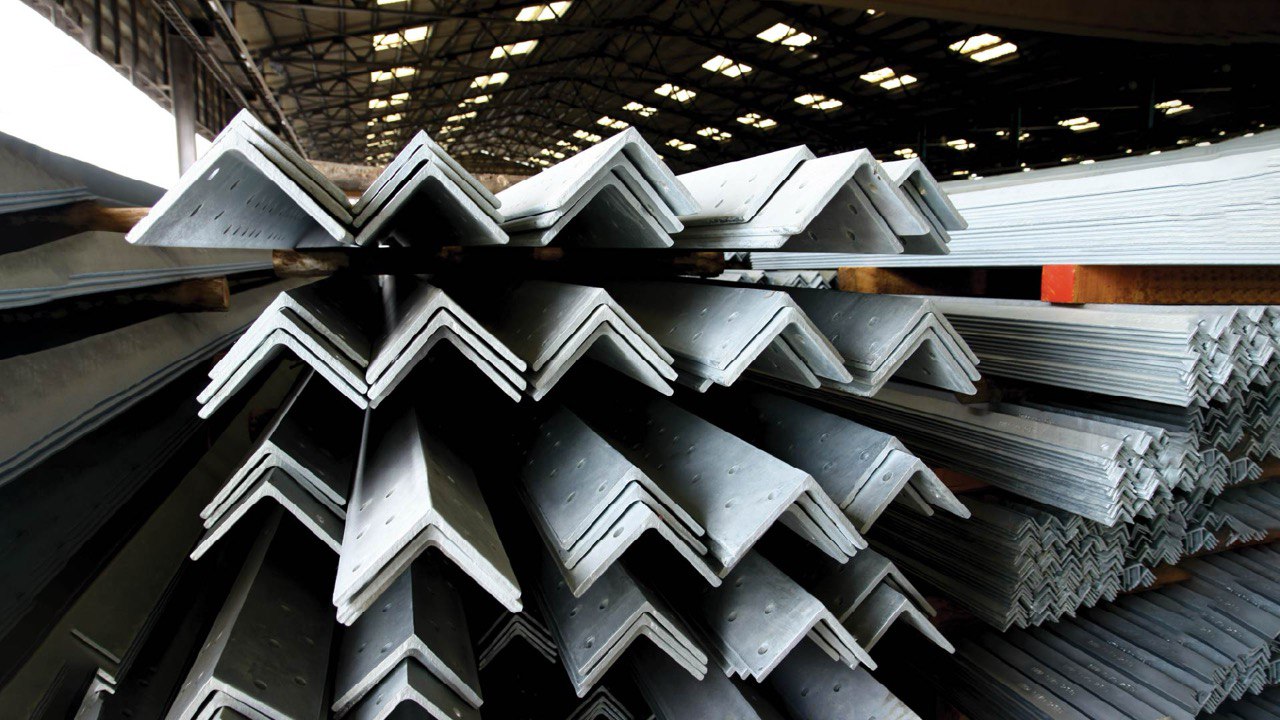

Galvanized Factory

Stands the Test of Time

At Fibo Gulf, our Galvanized Factory is built to produce steel components that last. From structural frames to roofing systems, our corrosion-resistant steel sheets, coils, and custom components power modern construction with unmatched durability. With automated roll-forming lines and precision cutting systems, we ensure every product is strong, reliable, and made to perform, whether it’s part of a skyscraper or a single-family home.

Roll-Forming Precision

100% Automated lines deliver consistent quality, speed, and material strength.

Corrosion Resistance

Galvanized coating protects steel in even the harshest conditions.

Structural Integration

Supports framing, roofing, and Fiboard panels with seamless fit.

Versatile Applications

Used across residential, commercial, and industrial projects.

From Sheet to Strength

Our production begins with raw steel coils, which are cleaned and prepared for galvanizing. The steel is then coated with a layer of protective zinc using a hot-dip or continuous galvanizing method, forming a corrosion-resistant barrier. Once galvanized, the steel passes through precision roll-forming and cutting systems that shape it into sheets, coils, or components based on each project’s specifications. Every product is quality-checked and ready for reliable performance.

Built Safe and Responsible

Health, safety, and environmental care are non-negotiable at our Galvanized Factory. Every process is monitored to protect workers from physical hazards and to prevent emissions or waste that could harm the surrounding environment. We train our team regularly, enforce strict PPE and safety systems, and invest in clean production methods. Because no material is truly strong unless the system behind it is safe and responsible.

Strength That Lasts

Engineered for performance, precision, and sustainability — our galvanized steel powers Fiboard systems and global construction markets with unmatched reliability.